Precise manual finishing

The secret behind this is the meticulous manual finishing of each element.

The perfect quality of our products does not come just from the highest class of our machinery, but also the team of top class specialist operators. We manually perfect each element that we produce, putting finishing touches on even the smallest detail.

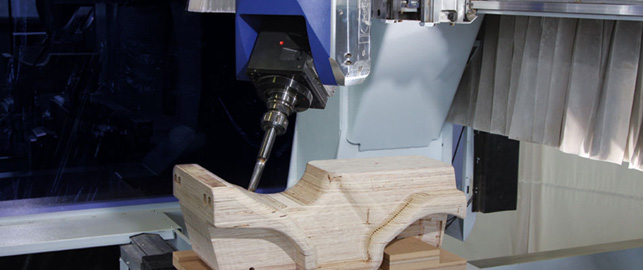

First, we prepare a graphic design, which is accepted by the client and then goes to production. This is the beginning of a process that is full of technological challenges and requires unusual care, but as a result every single execution, be it a single display stand or a multi-element set of instore furniture, is perfect in every detail. Elements are carefully cut on machines and delivered to specialists, who, given the high class tools at their disposal and many years of experience, create stands, cases, pieces of furniture and complicated exhibition systems of the highest quality. Our specialist treat each part individually and work on it as long as it takes to meet their very strict standards.

Then, teams composed of polishers, painters and assembly workers, are responsible for the final effect of an order executed for a client. In their hands, an inconspicuous form transforms into a visually attractive and perfectly executed piece of instore furniture. Before it happens, however, each part of the final object is carefully sanded, painted and polished. Only then, the team members efficiently assemble the whole product from the prepared parts using the best finishing and assembly elements available on the market. Such care and attention to detail pays off. As a result, our productions, regardless of their nature, show not only exceptional durability but also perfect execution and solid finish.