Plastic processing

Our hallmark is the wide palette of plastics and unlimited capability for making precise forms and shapes out of them.

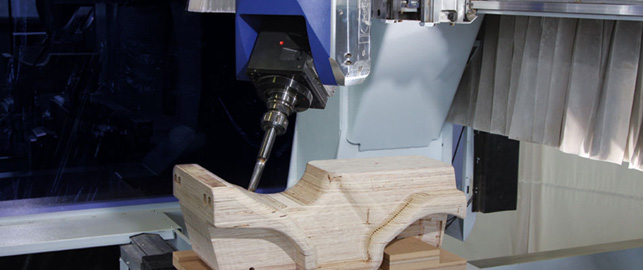

Our machinery park is equipped with the highest class machines and gives us nearly unlimited possibility of precise forming of a wide range of plastics and composites. The materials are selected to suit the needs and functions of the completed project. We have a very broad range of possibilities. We own machines for processing Plexiglas, MDF, Solid Surface and PVC. We can conjure any shape in any possible color. We manufacture both small advertising stands for flyers or catalogs, as well as designs with very complicated shapes of their structures, used for comprehensive furnishing of interiors and commercial space. Cutting out precisely even the smallest advertising elements, creating multi-element exhibition structures or engraving – those are just some of the possibilities offered by the laser cutter engraving machine owned by us.

The advanced technical capabilities of the laser cutter engraving plotter are especially important in our everyday production. When we prepare for you an advertising stand, a set of stands for flyers or decorate a store exhibition, we have at our disposal a machine that will not only cut the needed elements with exquisite precision but also mark them with a small logotype or trademark. The machine’s precision is visible both in details of huge construction projects as well as elements two centimeters long, such as a trademark engraved on a pen. Another advantage offered by the machine is that it works on most available surfaces. Our plotter engraves and cuts out shapes from most plastics available on the market and engraves patterns on glass. It cuts shapes out of thick or thinner Plexiglas with equal precision and a logotype engraved on a large stand is no different, apart from its size, from the same logotype placed on any advertising gadget.

As we prepare for you an advertising stand, store furniture, a fair stand or an entire commercial exhibition, we start with a graphic design. A specially prepared file goes to people operating our cutter engraving plotter. It is there that, in accordance with the technical specification (material, format, extra elements) all the project’s components are cut out. The precision of cut or engraved elements is very high – down to tenths of a millimeter. The materials prepared in the above manner are taken to a bender, which, through thermal processing, gives them an appropriate, even the most fanciful, shape. What is left then is the final finish and what you get is a durable and exceptionally precisely made product.