Thermoforming

An unlimited palette of patterns and shapes, both for small and large-sized formats.

This unique technology allows us to execute even the most complicated forms out of plastic. If there is any element crowning our machinery park, it is certainly thermoforming, or a technology of forming various solid materials in high temperatures. The machinery includes two enormous tabletops, with each of them serving a different function: the first heats the processed material making it pliable, whereas the second molds it to a desired shape using vacuum.

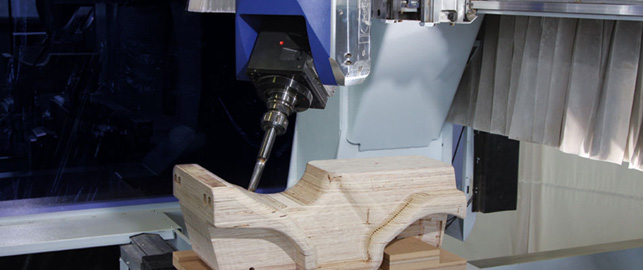

The form that may be produced by thermoforming depends primarily on the applied mold. This is a surface prepared earlier (cut out with a saw or milled with our CNC machine) on which the material is formed. This solution allows us to obtain virtually any shape – whether it is a small pond lining, a futuristic chair or sofa or a tabletop resembling stormy sea waves.

The impressive thermoforming technology allows us to manufacture even large-size products with very thin walls. This method offers an advantage of executing a wide range of fancy designs. The material thermoforming technology enriches our offering by adding another wonderful tool, which makes our clients’ exhibitions look exceptional and put no limitation on their form.